The sewage sludge carbonization plant is used to turn waste sewage into charcoal. This charcoal can be pressed into bricks and many other shapes. The charcoal can be used for heating and fueling sewage sludge carbonization plant. Charcoal is also used in a variety of products. It is also used to improve soil.

One of the top benefits of the machine is how eco-friendly it is. This machine takes sewage and processes it through carbonization. During the carbonization process, the sewage is heated to a high temperature where it is turned into carbon. The carbon is then pressed into charcoal bricks, chips, flakes or powder, depending on what your needs are.

This biochar reactor for sale is good for the environment since it takes waste and turns it into something useful. It helps make the environment better and it has anti-pollution equipment that stops dust from getting out into the environment. The machine also has a gas cleaner system so no gas pollution comes from the machine.

This machine is easy to run and the manufacturer will provide training and help you set up the machine. You also get after-sales service for the life of the machine. The machine uses a two-step carbonization process that will save you money and energy. Since the machine is designed to use less energy you will end up keeping your energy costs way down.

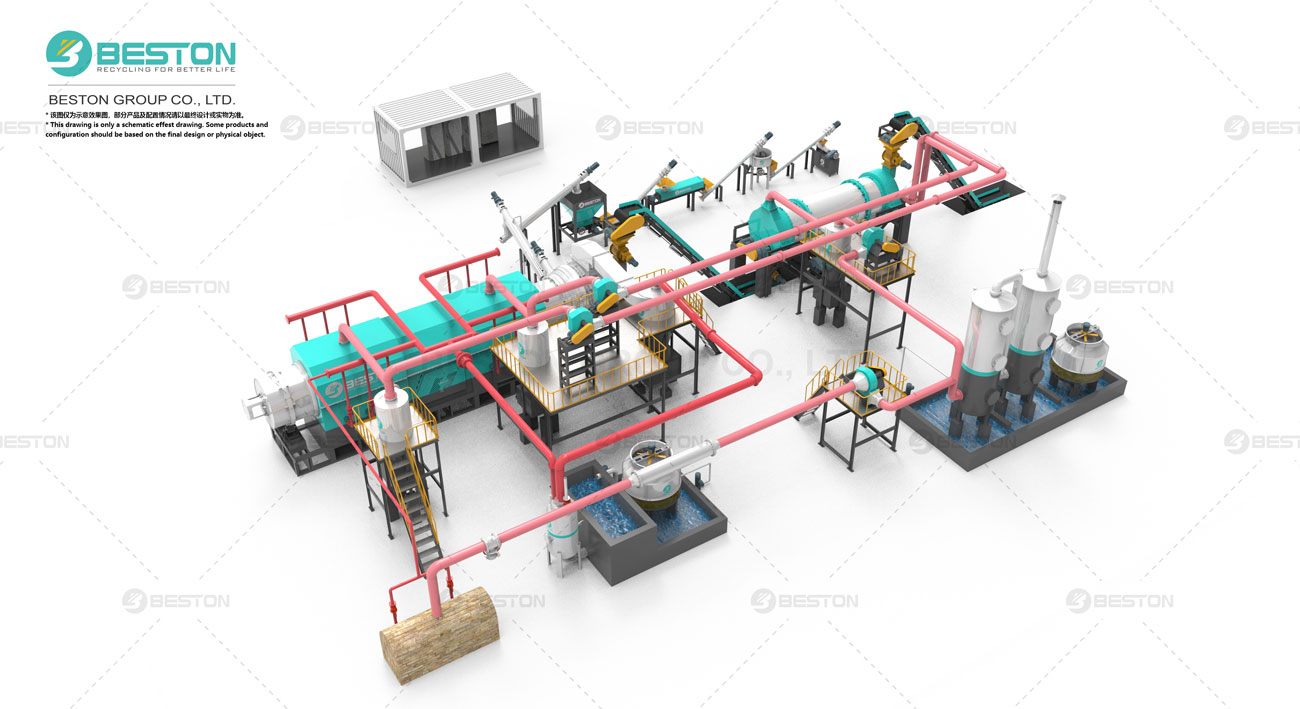

The machine works by taking the sludge into the machine through the measuring conveyor. After the sludge is measured it goes to the big dip conveyor where it is moved into the tumble dryer. The sludge has to be pre-dried before it can go into the machine. After the sludge has been predried it goes into the carbonization chamber and is dried out one more time. See some machine options on this page – https://bestonmachinery.com/charcoal-making-machine/wood/.

After the final drying process, the sludge is heated up to a very high temperature where it is turned into carbon. The carbon is ejected from the machine and it can then be processed into the final form. The machine runs on coal and it won’t produce any pollution into the air. This eco-friendly machine is a must for any recycling plant because it produces large amounts of carbon for a very affordable price.

The machine has all of the latest safety equipment which ensures that you can safely operate the plant. It will shut off quickly and the control system is very easy to learn and operate. Beston biomass pyrolysis plant cost will be a valuable investment for any business. If you wanna know the biomass pyrolysis plant cost, you can contact some manufacturers. This plant will help you make money from selling carbon and it helps the environment at the same time. The solid and dependable after-sales service ensures you can’t go wrong with this machine.