Pyrolysis is a reaction that is involved in the breaking down of large molecules into molecules of smaller size in a chemical reaction that takes place in the presence of heat. It is also referred to as thermolysis or thermal cracking.

Molecules vibrate at all temperatures, but this frequency of vibration is proportional to the heat. When an object is subjected to great heat, its molecules have increased vibrations, and this results in the stretching of the object and the higher vibrations resulting in their breakdown into smaller molecules, a process that is called pyrolysis. A biomass pyrolysis process is the thermal decomposition of the biomass that takes place when it is heated in the absence of oxygen. Both combustion and gasification are caused within the first two seconds of this fundamental chemical reaction. Find more information about biomass pyrolysis plant.

Biomass pyrolysis results in the production of biochar, bio-oil and other gases like carbon dioxide, carbon monoxide, hydrogen, and methane. Biochar is produced at temperatures lower than 450 degrees Centigrade and at low heating rates, while the gases get produced at high heating rates and in temperatures greater than 800 degrees. Bio-oil is the main product at intermediate temperatures.

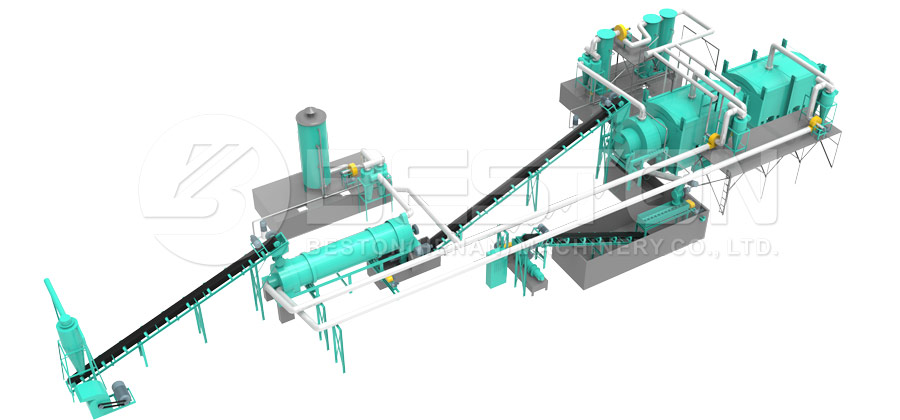

A charcoal making machine consists of a reactor in which the biomass is heated. The biomass that is fed into the reactor has to be dry and ground into small particles through drying and grinding equipment. The char produced in intermediate temperatures is separated into a cyclone and can be used for heating the reactor or for the drying of the biomass. At higher temperatures, the reactor produces gas and other components that are cooled and collected to form bio-oil. The gas produced can also be used for heating the reactor or for drying.

A biomass pyrolysis plant can be small scale and installed in a remote location that leads to a reduction in handling and transport cost of the biomass. It is a process that offers a flexible way of converting biomass solids from agricultural harvesting operations to produce bio-oil that can be easily stored and transported for use in chemical and power plants.

The pyrolysis process allows for the use of a wide range of feedstock from biomass. The process is highly dependent on moisture content and this has to be lower than 10 percent. That is the reason that drying units are a part of biomass pyrolysis plants. The efficiency of the plant is also dependent on the particle size of the feedstock, and plants function best when these sizes are kept to a maximum of 2mm. That is the reason grinding equipment is part of the coconut shell charcoal making machine and this operation is carried out after the biomass is dried.

Slow pyrolysis results in biochar as the main product, while fast pyrolysis will produce 60 percent of bio-oil, 20 percent of biochar, and 20 percent of syngas, and takes seconds to complete. Biochar and gas can be used for producing the heat required for pyrolysis. The oil is a useful byproduct that has sufficient commercial value. Get high quality biochar production equipment here.