Sludge is a solid by-product comprising bio-waste from a plumbing and drainage system. The sewage treatment process is a delicate one, and should be carried out with utmost caution. The sludge management system is mainly tasked with reducing the sludge weight and the space it occupies, therefore yielding reduced costs in the treatment process.

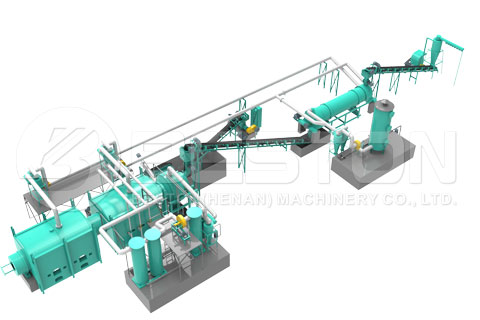

Treatment Plant Components and Their Functions

The sewage sludge treatment process goes through three stages: thickening, digestion and water separation. The treatment plant has tanks that store the sludge temporarily to achieve gravity thickening. The lighter material floats on the surface of the floatation tank and the thickened sludge is deposited at the bottom. Some treatment plants will utilize a process called dissolved air floatation. This process introduces air bubbles into the mixture causing the less dense solid materials to float, leaving sludge below.

The dewatering chambers are responsible for reducing the amount of water in the mixture. The reason for this activity is to turn the sludge into an easy-to-compost mixture. Centrifugation of the sludge utilizes centrifugal forces in the chambers to make the solid materials settle on the edges before the filtration process.

Filtration Chambers

Different sewage carbonization machine uses different filtration techniques. One of the main techniques is the use of sand drying beds, though they consume much space. For a drying bed, the layers of gravel and sand are spread and stack at different heights. The layer on top comprises coarse gravel, followed by a layer of finer gravel. The bottom part of the bed is made up of sand.

Belt Filter System

The belt filter system harnesses the power of both gravity and pressure. During the gravity stage, temperatures are increased to remove water through evaporation.

Thermal Hydrolysis Reactor

Products from the processes above contain high amounts of phosphorus. As such, a thermal hydrolysis system is used to remove phosphorus, which corrodes plant equipment and prolongs the digestion process. In the reactor, protein molecules in the sludge are broken to small molecules, which makes it easier for bacteria to act on. A flash tank is also incorporated, after which pressure is reduced, making the material ready to be pumped to the digester.

Anaerobic Digester

The digestion process uses anaerobic bacteria to breakdown the protein molecules and other bio compounds. In the bio digester, the mass of the waste is reduced significantly by the acids formed during the decomposition process. The end product from digester tanks contains methane and carbon dioxide. Methane is combustible, and is therefore harvested through pipes connected to the top of the digester. For effective anaerobic digestion, enzymes are introduced to the digester tanks to speed up the charcoal manufacturing process.

Aerobic Digester

In some instances, aerobic digestion is applied in digesting the sludge. Oxygen diffusing systems are used to introduce oxygen in the mixture in the form of air bubbles. In the presence of oxygen, organic matter is consumed by bacteria, converting it into carbon dioxide. The advantage of aerobic digesters is that they are faster in digestion than the anaerobic ones. However, they are expensive to install and maintain.

Disposal is done depending on the source of the sewage. Sewage from industrial parks has complex chemicals, and therefore not suitable for agricultural purposes. Read more: https://www.bestongroup.com/.