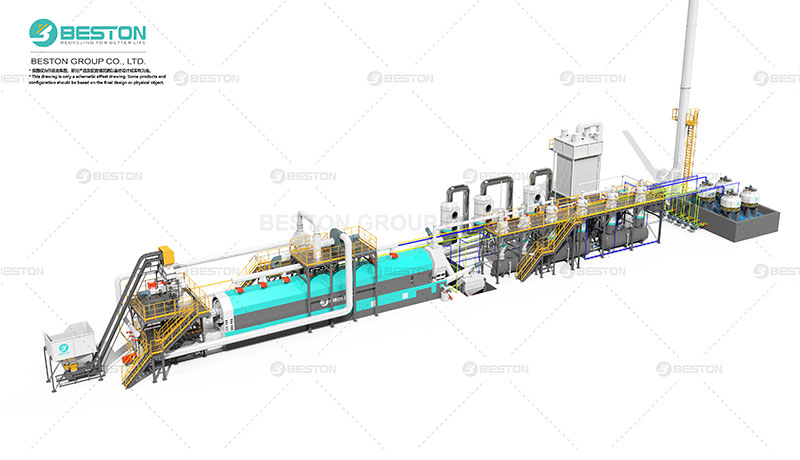

Waste tires pyrolysis plants produce carbon black and other compounds. These compounds are useful for various purposes including fuel, building bricks with clay, tires, and more. The gas produced by the waste tire pyrolysis process is recycled to heat the reactor. After oil is produced, the temperature in the reactor will be cooled and carbon black and steel wire will be discharged manually.

Carbon Black Is Produced by Pyrolysis

A waste tires pyrolytic plant(https://www.bestoneco.com/maquina-de-reciclaje-de-llantas/) is capable of producing carbon black. It is also capable of producing activated carbon. Carbon black is a product of pyrolysis, a chemical process in which a waste tire is burned. The process uses a one-step chemical activation process, using sulfuric acid or hydrogen peroxide in a ratio of 1:4.

The proposed research could lead to the recycling of a huge stream of solid waste – currently the majority of which ends up in landfills. Carbon black, one of the most important industrial byproducts, is recycled and reused. As a byproduct of this process, the recovered carbon black can be used for tire manufacturing, a large-scale industry. By modifying the existing process, the proposed technology can stimulate a thriving industry and provide more opportunities for pyrolysis plant owners.

It Can Be Used as Fuel

A tire pyrolysis plant is an industrial process that turns waste tires into oil. However, as with any industrial process, this type of plant needs regular maintenance to maintain optimal productivity, decrease operating costs, and maximize return on investment(máquina de reciclaje). In this article, we’ll examine the advantages and disadvantages of catalytic versus thermal pyrolysis and discuss the benefits and limitations of each process.

The best temperatures for oil production range between 425 and 720 degC, with maximum yields of 38 to 60 percent. The optimal temperatures can vary, but these fluctuations are likely related to differences in heating rates, gas residence time, and reactor type. Additionally, the mass flow rate and particle size of waste tires play an important role in the yields. In addition to the optimal temperature, secondary reactions occur during the conversion of gaseous and liquid compounds into fuel.

It Can Be Made Into Pellets or Briquettes for Burning

The main benefits of this pyrolysis process are high caloric values, low toxicity, and odor-free products. Fuel pellets can be stored for up to three years without degradation and can be easily transported and conveyed. Their regular sizes make them easier to transport and burn. In order to be effective, a waste tires pyrolysis plant must first process municipal wastes, including tires and rubber, and add binder agents.

Waste tires recycling plants(planta pirolisis neumaticos) have different types of fuels that are suitable for burning. The oil yield of truck and OTR tires is 52% and 35%, respectively. Other fuels can be made from these materials, including activated carbon. The pyrolysis oil produced can be used for fuel production in steel mills, boiler heating, and heavy oil generators. The residual fuel can be further refined and used in low speed engines. In addition to fuel, waste tires pyrolysis plants also produce other products like pellets and briquettes for burning.

It Can Be Used for Construction Bricks With Clay or for the Production of Tires

A waste tires pyrolysis plants(planta de reciclaje de neumaticos) converts waste tires into a wide variety of useful resources. These end products can include carbon black, fuel oil and gasoline. Besides, the pyrolysis oil from tires can also be used in the production of construction bricks and steel wire. The end products of this plant are highly sought after and sell well in the market.

The tires’ gas and liquid fractions contain aromatic and Asiatic hydrocarbons, hydroxyl compounds and lignin. The major pollutant gases produced during the process include SO2, NOx, and polycyclic aromatic hydrocarbons (PAHs). The char produced is rich in fixed carbon and inorganic matter.