In the realm of sustainable and eco-friendly practices, charcoal making machine plays a vital role. Charcoal is not only a versatile fuel source but also finds applications in various industries, such as agriculture, metallurgy, and cooking. To embark on this journey of charcoal production, it is crucial to equip oneself with a reliable and efficient machine. In this article, we will delve into the necessary preparations one should undertake before purchasing a charcoal machine.

Researching Charcoal Equipment

Before investing in a charcoal maker machine, it is essential to have a comprehensive understanding of the different types available in the market. Traditionally, charcoal has been produced using methods like kilns and pit burning, but modern technologies have introduced advanced machines with improved efficiency and output. By studying the various types, one can determine which suits their specific requirements.

Analyzing features and specifications is another critical aspect of the research process. Production capacity, measured in kilograms or tons per hour, determines the machine’s output potential. Energy efficiency is crucial to minimize operational costs and environmental impact. Furthermore, considering the compatibility of different raw materials with the machine’s design and capabilities ensures optimal performance and versatility.

Evaluating Quality and Durability

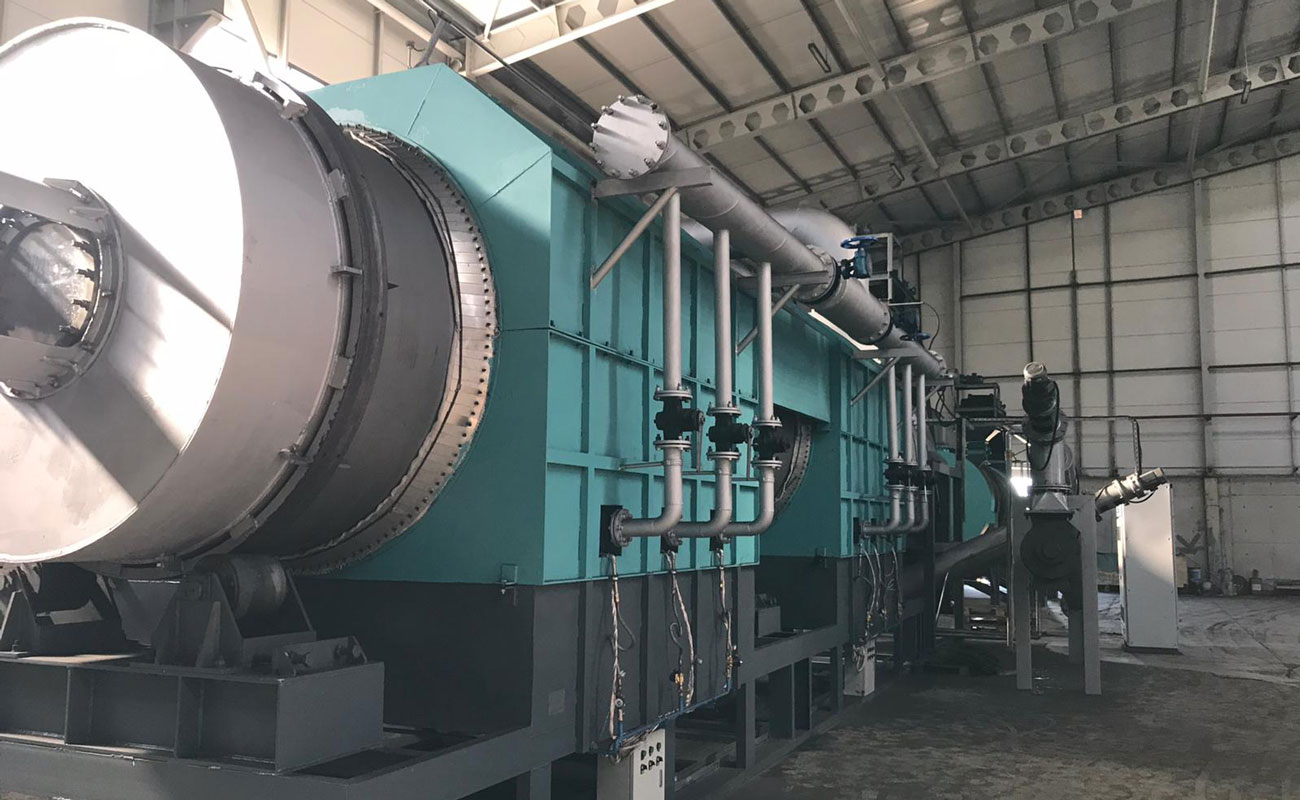

When investing in a charcoal making machine, it is paramount to assess its quality and durability to ensure a long-term investment. Examining the construction materials used in the machine’s manufacturing provides valuable insights into its sturdiness and resistance to wear and tear. Machines constructed with high-grade steel or alloy materials generally exhibit superior durability.

Build and design play a vital role in a machine’s performance and longevity. Advanced welding techniques, such as TIG or MIG welding, enhance the machine’s structural integrity. Reinforcement mechanisms, such as gussets or additional support beams, contribute to the machine’s ability to withstand the rigors of continuous operation.

Considering Safety Measures

Safety should be a top priority when purchasing a charcoal kiln for sale. Fire safety features, such as fire-resistant coatings, automatic extinguishing systems, and temperature monitoring devices, mitigate the risk of accidents and potential fire hazards. Emission control systems, like scrubbers or catalytic converters, help minimize harmful emissions, ensuring compliance with environmental regulations.

Operator safety precautions should not be overlooked either. Safety shields, emergency stop buttons, and comprehensive training programs are essential components of a safe working environment. Prioritizing safety features not only protects the workforce but also minimizes the risk of operational disruptions.

Comparing Prices and Cost-effectiveness

While the initial investment is a significant consideration, it is crucial to evaluate the long-term benefits and cost-effectiveness of a charcoal manufacturing machine. A higher upfront cost may be justified by increased production capacity or improved energy efficiency, resulting in substantial savings in the long run. Therefore, it is essential to weigh the initial investment against the projected returns.

Thorough research on market prices allows potential buyers to gauge the prevailing rates and make informed decisions. Additionally, analyzing operating costs, such as maintenance, raw material expenses, and energy consumption, enables an accurate assessment of the machine’s overall cost-effectiveness.

Seeking Reliable Suppliers

Identifying reliable suppliers is pivotal in acquiring a high-quality charcoal making machine. Researching a supplier’s reputation and reading customer reviews provide insights into their product quality, after-sales service, and overall reliability. A supplier with positive feedback and a track record of customer satisfaction is more likely to deliver a satisfactory product.

Warranty and after-sales support are also crucial considerations. A reliable supplier should provide a warranty period, covering any potential manufacturing defects or malfunctions. Additionally, prompt after-sales support ensures quick resolution of any issues that may arise during operation.

Establishing direct communication with the supplier enables potential buyers to clarify any doubts, seek technical information, and negotiate favorable terms. Clear and transparent communication channels lay the foundation for a successful partnership.

As an experienced manufacturer, Beston Group has established charcoal making project cooperation with customers all over the world. Thus, consider this company your go-to supplier when you consider investing in charcoal making machine.

Conclusion

In conclusion, purchasing a charcoal making machine requires thorough preparations to make an informed decision. By researching different types of machines, analyzing features and specifications, evaluating quality and durability, considering safety measures, comparing prices and cost-effectiveness, and seeking reliable suppliers, individuals can ensure a smooth transition into the world of charcoal production. Investing time and effort in these preparations will pave the way for sustainable and efficient charcoal production, contributing to a greener future.