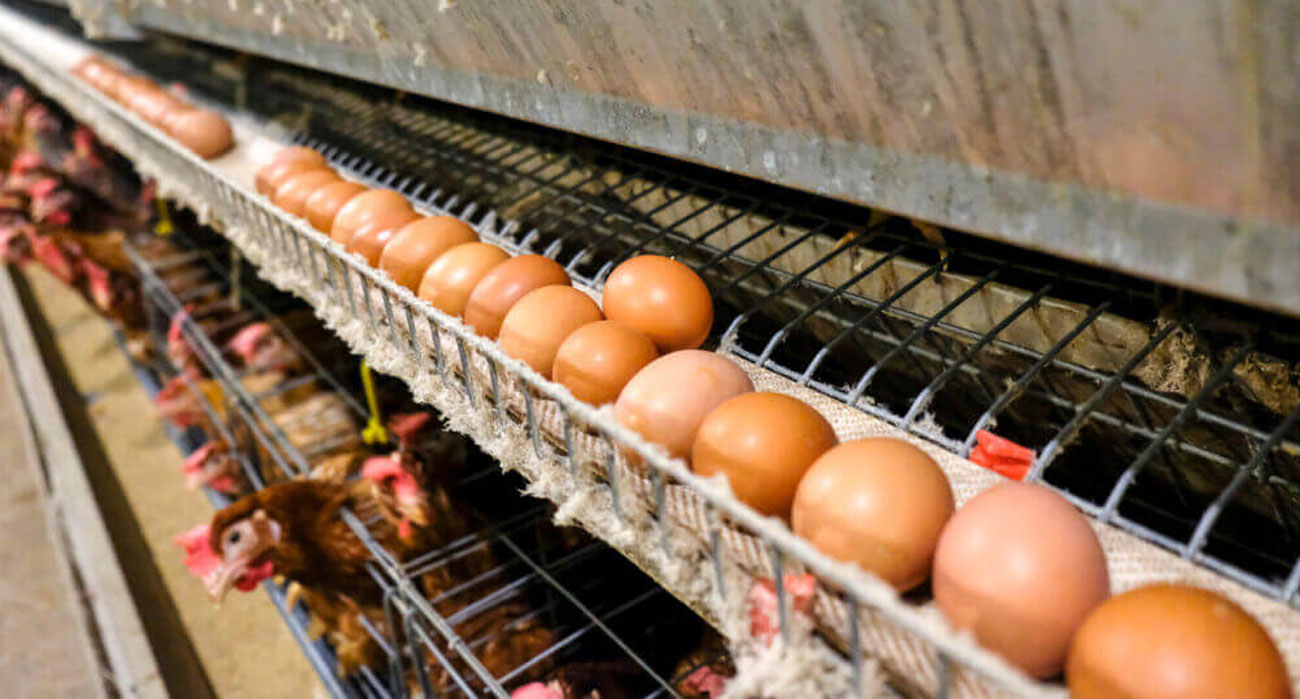

The versatile chicken egg is a high-value ingredient in every cuisine across the planet. The great demand for eggs means that as many as 3 billion eggs are in transit from hen houses to commercial and domestic kitchens at any given moment. To ensure that these delicious but delicate orbs of goodness reach their destinations intact, there is an equally great demand for sturdy egg tray cartons and pulp-molded trays — and this is where egg tray-making machines come into the picture.

Getting the best price for a top-quality egg tray production machine can help you maximize your profits in meeting the limitless demand for top-quality egg trays. An egg tray making machine can create a product in high demand from a wide range of recyclable materials. In the following article, we will cover some important points to consider when purchasing these machines that will enable you to fetch the best price and product for your business.

Operations and Budget

The first thing to consider will be the size of your project and operations. If you are providing egg trays for a large poultry farm or several large poultry operations, there are large egg tray making machines that can produce upwards of 10,000 trays in a single hour. But if you are running a smaller or medium operation, there are machines that produce 500 to 3,000 egg trays per hour.

The most efficient solution will be the fewest number of machines operating at full capacity. For example, it is better to have two small machines operating at full capacity than a very large machine operating at half capacity.

Budget

Next, you should consider your budget. If you know exactly how much you will be investing into this project, you will have a clearer idea of the type of machine that best suits your needs. Remember that your budget should not only calculate for the initial industrial packaging machine price, but the ongoing costs of replacement parts, services, repairs and so forth. Many machines will have a cheaper egg tray machine price but will cost much more in ongoing care and maintenance.

Automated/Manual — there are automated machines and manual options that provide different advantages. The automatic option is a great idea for large-scale operations where they can reduce the need for operators to assist in production. Automatic egg tray making machines are more costly initially and in ongoing care and maintenance.

Then there is the manual variety that will not cost you very much initially or in ongoing care and maintenance. Nevertheless, you will still have to pay for operators to assist with the process.

More details: https://pulpmouldingmachines.com/egg-tray-making-machine/automatic/.

Other components — you will also find that the technology involved in the design and creation of egg tray making machines is constantly being upgraded and enhanced. For example, wet pulp trays must dry quickly and thoroughly to achieve the proper rigidity. For climates that are especially cold or humid, there are special dryer components that will quickly dry out the wet pulp molds, so they are ready for marketing rapidly.