In the pursuit of sustainable energy solutions, plastic pyrolysis has emerged as a promising technology for converting waste plastic into valuable resources. Pyrolysis involves the thermal decomposition of organic materials in the absence of oxygen, resulting in the production of pyrolysis oil, a valuable feedstock for various industrial applications. To achieve large-scale production of plastic pyrolysis oil, a systematic approach and advanced technology are imperative.

Understanding the Continuous Plastic Pyrolysis Plant

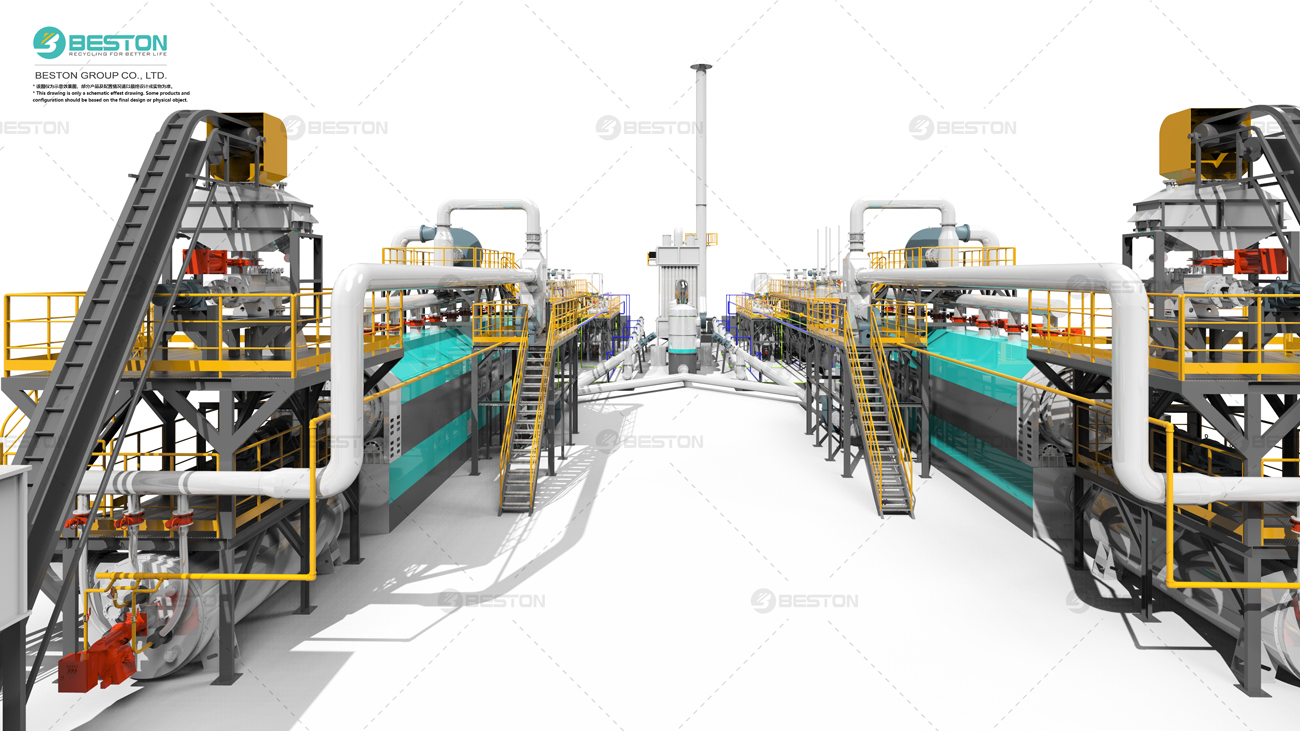

A pivotal component in large-scale production is the continuous plastic pyrolysis plant. This sophisticated apparatus is designed to handle a high volume of plastic waste continuously, ensuring efficiency and productivity. The plant consists of several integrated units, each playing a crucial role in the pyrolysis process.

Feedstock Pre-treatment

The process begins with the preparation of feedstock, which involves sorting, shredding, and cleaning the plastic waste to remove contaminants and ensure uniformity. The feedstock is then fed into the pyrolysis reactor, where the actual conversion takes place.

Pyrolysis Reactor

The heart of the continuous plastic pyrolysis plant is the pyrolysis reactor for sale, where the plastic waste undergoes thermal decomposition at elevated temperatures. The reactor is carefully engineered to optimize heat transfer and maximize the yield of pyrolysis oil while minimizing energy consumption.

Heat Management System

Maintaining optimal operating temperatures is critical for efficient pyrolysis. A sophisticated heat management system regulates the temperature inside the reactor, ensuring consistent performance and preventing thermal degradation of the pyrolysis products.

Gas and Oil Separation

During pyrolysis, various gases are produced along with pyrolysis oil. An efficient gas and oil separation system is essential for recovering and purifying the valuable pyrolysis oil while capturing and recycling the by-product gases for energy generation or further processing.

Product Recovery and Refining

Once separated, the pyrolysis oil undergoes further refining to remove impurities and enhance its quality. Advanced filtration and distillation processes are employed to produce a high-grade pyrolysis oil suitable for use as a fuel or chemical feedstock.

For more information on plastic to oil solutions, please contact Beston China.

Key Strategies for Large-Scale Production

Achieving large-scale production of plastic pyrolysis oil requires a comprehensive strategy that addresses technical, logistical, and regulatory challenges. Here are some key strategies to consider:

Technology Integration

Investing in state-of-the-art pyrolysis technology is essential for maximizing production efficiency and product quality. Continuous improvement and innovation in reactor design, heat management, and product refinement are critical for staying competitive in the market.

Feedstock Supply Chain Management

Ensuring a consistent and reliable supply of plastic waste is crucial for uninterrupted operation of the plastic pyrolysis machine. Establishing strategic partnerships with waste management companies, municipalities, and recycling facilities can help secure a steady stream of feedstock.

Scale-Up and Optimization

Scaling up production requires careful planning and optimization of process parameters. Conducting thorough feasibility studies, pilot testing, and process modeling can help identify potential bottlenecks and optimize the plant design for maximum throughput and profitability.

Compliance and Environmental Sustainability

Adhering to regulatory requirements and environmental standards is non-negotiable in the plastics pyrolysis industry. Implementing robust emissions control measures, waste management protocols, and sustainable practices are essential for maintaining regulatory compliance and public trust.

Conclusion

Large-scale production of plastic pyrolysis oil holds tremendous potential for addressing the dual challenges of plastic waste management and energy sustainability. By leveraging advanced technology, strategic planning, and sustainable practices, businesses can unlock new opportunities for generating value from plastic waste while contributing to a cleaner, greener future. Embracing innovation and collaboration will be key to realizing the full potential of plastic pyrolysis as a viable solution for the circular economy.